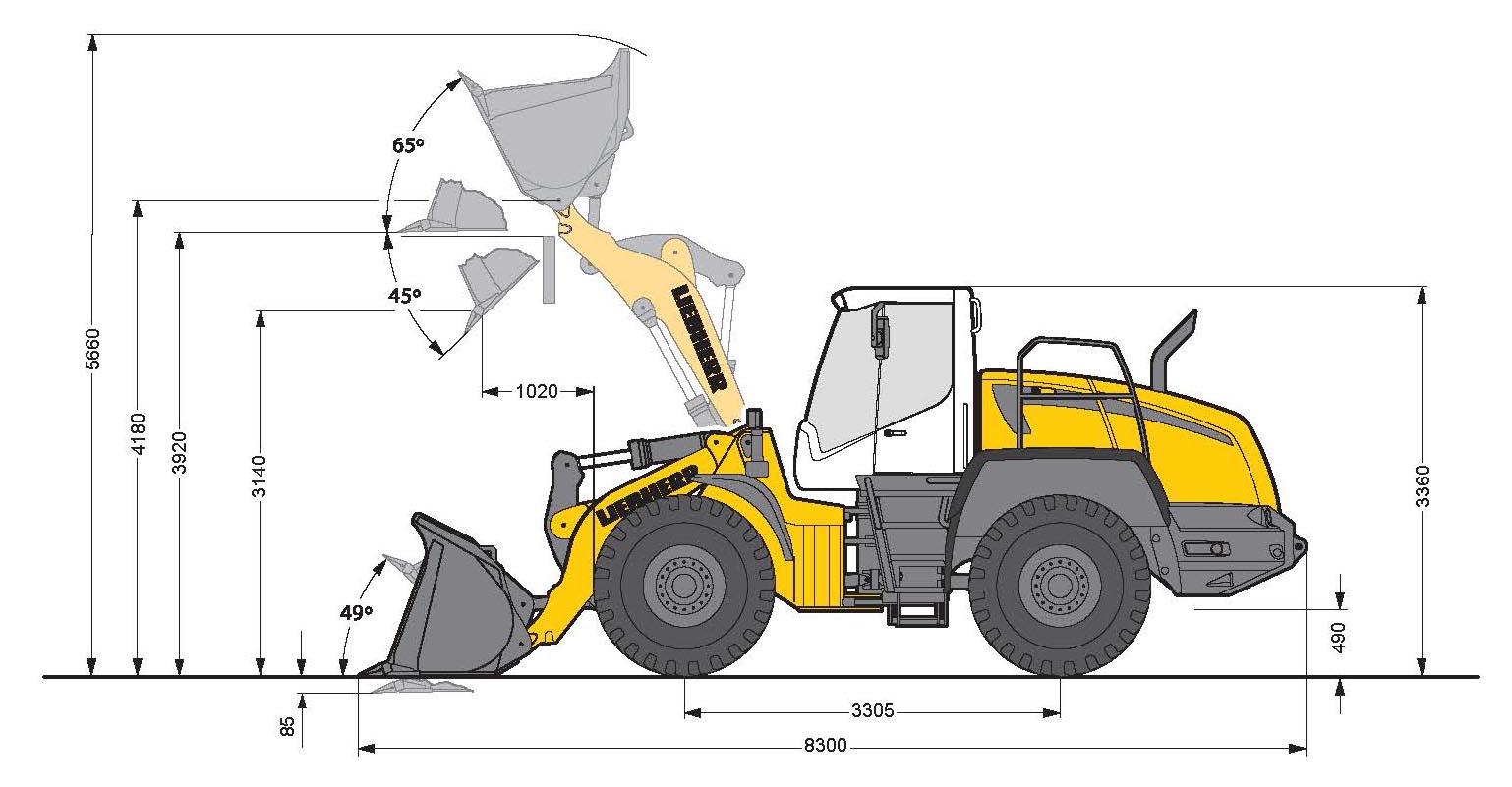

Performance

Liebherr wheel loaders are specially designed for your market to meet the highest requirements. The ideal positioning of the Liebherr driveline moves the center of gravity to the rear of the wheel loader – meaning increased stability and no lifting of the rear. This greatly increases the handling capacity per operating hour compared with conventional wheel loaders.

Tipping load, articulated: 12,350 kg

Bucket capacity: 3.2 m³

Operating weight: 17,350 kg

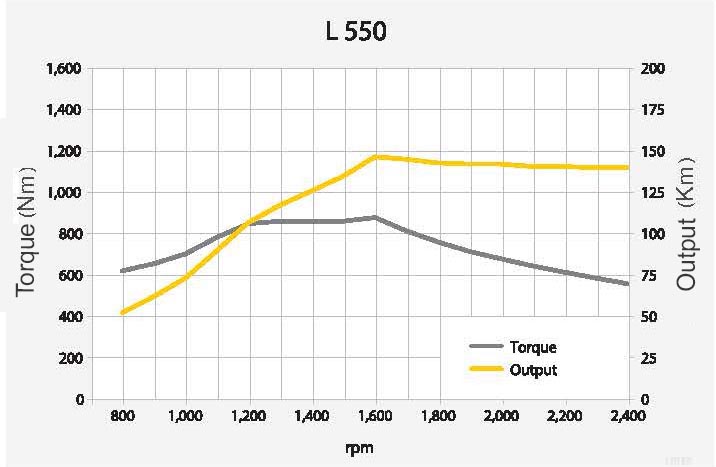

Engine output: 147 kW / 200 HP

Comfort

The ultra-modern cabin design with advanced ergonomics, Liebherr driveline, optimal weight distribution and excellent maintenance access lead to unequalled overall comfort and simple service.

L 550

Driveline

Stepless hydrostatic travel drive

Design

Swash plate type variable flow pump and two variable axial piston motors in closed loop circuit and axle transfer case. Direction of travel is reversed by

changing the flow-direction of the variable-displacement pump

Operator’s Cab

Design ______________________________ On elastic bearing on rear section, soundproof

ROPS / FOPS cab.

Operator’s door with 105° (L 550) / 180° (L 566, L 580) opening angle, ventilation opening on the right hand side, front windscreen made of compound safety

glass, green tinted as standard, side windows made of single-pane safety glass, grey tinted, continuously adjustable steering column and joystick control as

standard, heatable rear window ROPS roll over protection per DIN/ISO 3471 / EN 474-1 . FOPS falling objects protection per DIN/ISO 3449 /EN 474-1

Brakes

Wear-free service brake Self-locking of the hydrostatic travel drive (acting on

all four wheels) and additional pump-accumulator brake system with wet multi-disc brakes (two seperate brake circuits)

Steering

“Load-sensing” swash plate type variable flow pump

with pressure cut-off and flow control. Central pivot with two double-acting, damped steering cylinders.

For download catalogue, Click on the link